PRODUCTS

MESSAGE

Product Details

Chemical Composition

(1) Copper value includes Silver

Note: Copper + Sum of Named Elements, 99.7% min)

Applicable Specifications

Common Fabrication Processes

Bending, Cold Working, Drawing, Extruding, Forging, Heading, Hot Working, Impacting, Rolling, Swaging.

Fabrication Properties

Mechanical Properties

Typical Room Temperature 20°C

* Vickers Hardness is approximate – converted from Rockwell Hardness using ASTM E140 tables

Physical Properties

.* Solution heat treated, cold worked (50% minimum) and aged.

Typical Uses of Chromium Copper

Consumer – Pencil-type & Light Soldering Guns: Tips, Rod Extensions

Electrical – Electrical Connectors, Electron Tube Grid Side Rods, Circuit Breaker Parts, Thermal Conductors Requiring Greater Strength than Copper, Cable, Electric Motor and Generator Components, Wire, High Temperature, Parts for Electronic Devices, Semi Conductor Bases, Contacts, Connectors, Switch Contacts, Electrical Conductors Requiring Greater Strength than Copper, Arcing and Bridging Parts, Switch Gears

Industrial – Plastic Mold Components, Structural Parts, Spot Welding Tips, Flash Welding Electrodes, Molds, Electrode Holder Jaws, Flash Welding Electrodes, Seam Welding Wheels, Current Carrying Shafts and Arms, Heat Sinks, Resistance Welding Machine Electrodes, Wear Plates on Heavy Equipment.

RWMA (Resistance Welder Manufacturers Association) Chromium Copper

Electrode Material Standards

The mechanical and physical properties required of electrodes vary according to the application. The materials being used for electrodes fall into three groups:

• Group A — Copper Base Alloys.

• Group B — Refractory Metals and Refractory Metal Composites.

• Group C — Specialty Materials.

These groups are further subdivided as follows:

GROUP A. Copper Base Alloys

RWMA Class 1. Specifically recommended, because of its high electrical and thermal conductivity for spot welding aluminum alloys, magnesium alloys, some coated materials, brass and bronze.

RWMA Class 2. Class 2 material has slightly lower conductivity and higher mechanical properties than Class 1. Class 2 are general purpose resistance welding electrode materials for production spot and seam welding of most materials. They are suitable for spot welding electrodes, projection welding electrodes, seam welding electrodes, shafts and bearings, flash welding electrodes and current-carrying structural members, and are also available as high strength and high electrical conductivity castings for use as welding platens and secondary circuit structural members. Class 2 material should be used in the heat-treated condition.

These materials are stronger than Class I materials, but have slightly lower conductivity. They are used for the spot and seam welding of cold and hot-rolled steel, stainless steel and low conductivity brass and bronze. They are also used as flash welding dies and as electrodes for the welding of galvanized steel and other coated materials.

RWMA Class 3. Class 3 material has lower conductivity and higher mechanical properties than Class 2. It is recommended for projection welding electrodes, flash and upset welding electrodes, current-carrying shafts and bushings. As castings, Class 3 material is recommended for highly stressed welding structural current-carrying members and heavy-duty offset electrode shanks and holders. It is recommended for spot welding and seam welding steels having high electrical resistance, such as stainless steels, and it should be used in the heat-treated condition.

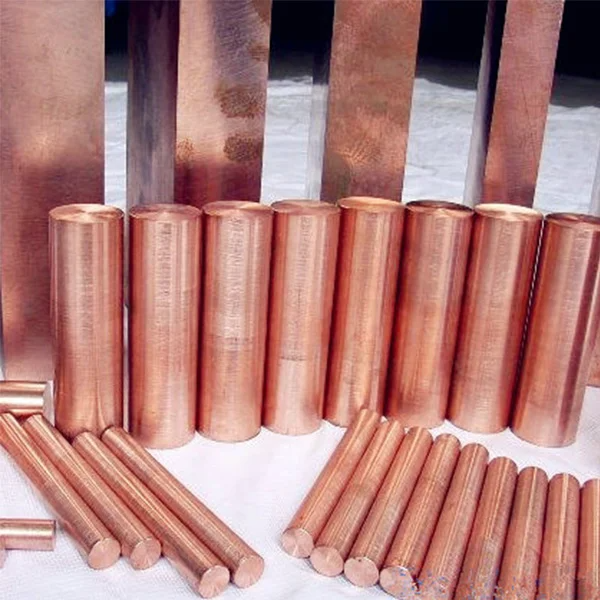

Chromium Copper C18200 Extruded Rod

Available from Austral Wright Metals

Message

Related Products

Please give us a message

Tel