PRODUCTS

MESSAGE

Product Details

Tellurium copper is tellurium and copper alloy and a kind of tellurium bronze materials, this kind material contains 0.4-0.7%’s tellurium, which makes tellurium copper alloy have good machining performance; Copper telluride containing 50% tellurium and 50% copper is used as an intermediate alloy. In ASTM standard it is named C14500, In GB standard named QTe0.5, In JIS named C1450, in DIN named CuTeP and in BS it is named C109. C14500 tellurium copper alloy is with high conductivity and free cutting copper alloy material, its development is aim to fill the gap of copper alloy precision processing materials. C14500 tellurium copper alloy material has both good free cutting performance and excellent electrical& thermal conductivity, meanwhile it is with good corrosion resistance and electric ablation resistance. Besides, C14500 tellurium copper has good cold and hot processing performance, can be forged, cast, extruded, drawn and molded by punching.

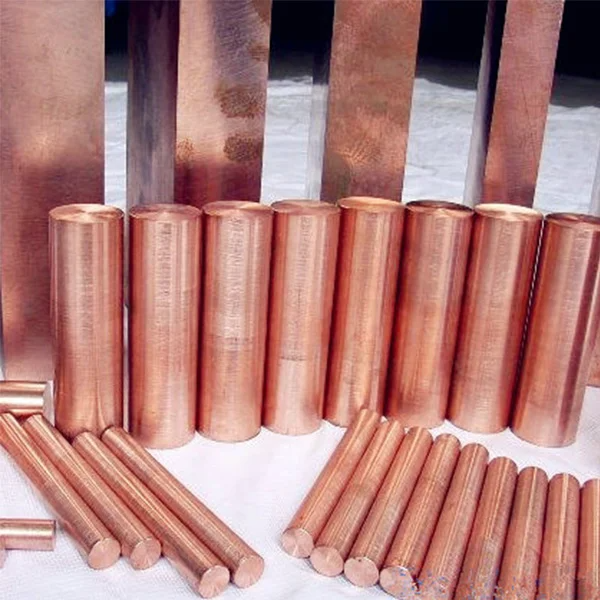

Popular Products of C14500 Tellurium Copper Alloy: C14500 Tellurium Copper Plate, C14500 Tellurium Copper Sheet, C14500 Tellurium Copper Bar, C14500 Tellurium Copper Wire, C14500 Tellurium Copper Pipe and Other Profiles.

Standards& Names:

Chemical Composition:

Main Applications:

C14500 Alloy is mainly used for precision electronic and electrical components with high conductivity and corrosion resistance, advanced mechanical and electrical parts, forgings and threaded cutting parts, plumbing fittings, electrical contacts, plasma and laser cutting parts, automobile starter and switch parts, etc. In recent years the new energy vehicles are promoted widely, C14500 Alloy has been successfully applied in the field of large current connector of new energy vehicles.

Mechanical Property:

Physical Property:

Machining Property:

All above products from TJC STEEL can be supplied with certified doc by LR, KR, RINA, NK, BV, SGS, TUV, ABS, VL, etc; Mill certificate will be comply with EN10204 3.1 or EN10204 3.2 accordingly.

Message

Related Products

Please give us a message

Tel